Family Based

Everyday People

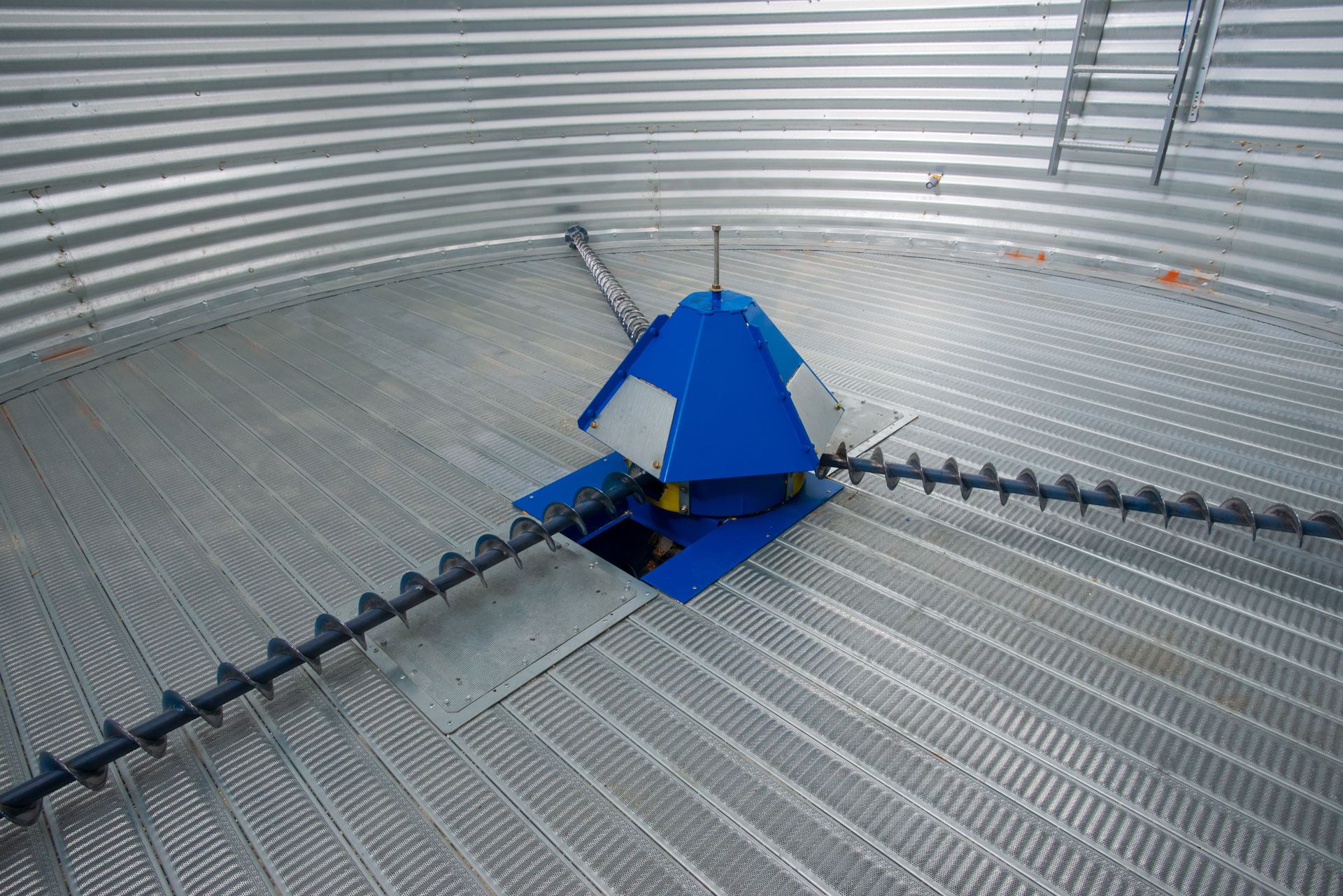

The family-owned company got its start when brothers Charles and Gerald Shivvers developed and patented a tapered sweep auger that significantly improved the flow and transfer of grain within a bin compared to conventional augers at the time.

Shivvers offers a complete line of high-volume, high-efficiency, fully automatic grain handling and drying options with capacities of 6,000 to 52,800 bushels per day.

Designed and manufactured in the U.S.A, no other brand – no other drying system – can match the combination of built-in surge capacity, efficiency and flexibility of Shivvers Performance Systems.

Why Do Farmers Choose Shivvers?

Simple. Because we engineer grain drying systems that let you focus on harvest.

This means less time babysitting, less money spent operating, higher test weights, and more money in your pocket. Shivvers Grain Dryer Systems consistently maintain higher test weights, maximize energy usage, and saves time for our customers—enough to quickly pay for the system.

Counter-Flow Drying Efficiency

Shivvers Systems operate with 36 to 96 inches of grain depth. This means that the air you paid to heat passes through a much larger volume of grain before being exhausted from the drying process, ensuring it is always used to its maximum moisture-holding capabilities.

Automated Drying Operation

Precision control and automation, achieved through Shivvers computerized Command Center control units, means having enough surge capacity for the dryer to run 24 hours a day, 7 days a week. Concentrate your efforts on harvest with peace of mind.

Multi-Crop Drying Capability

A Shivvers system maintains its efficiency and delivers excellent capacity, whether at lower 90º – 160º temperatures commonly used with specialty grains, or dry yellow field corn at 200ºF. These efficiencies, allow operators to dry a variety

of crops.

Remote Management Capabilities

Manage your drying operation with a smartphone, PC or tablet anywhere you have internet access. While some competitive systems allow remote monitoring capabilities, the Shivvers Link Remote Management System takes this two steps further, adding remote control functionality for both your drying & storage operation.

How It Works

Shivvers Systems are integrated into grain bins to offer a comprehensive solution for drying, handling, and storing grain, transforming the entire bin into a drying system. Available in 2 main system types, both the Circu-Lator and Dri-Flo Systems utilize the highly efficient Counter-Flow Drying Process.

This system includes a grain spreader, core machine, computerized Command Center control unit, raised drying floor, heater, and a series of transfer augers to transport dry grain from the drying bin to storage bin(s).

Shivvers Grain Drying Machines

Rugged, Reliable, and Engineered for High Capacity and Durable Performance.

Highly flexible and versatile, each Shivvers Performance System can match your current and future grain drying needs — for new as well as existing grain operations. Individual components can also be used to upgrade existing in-bin systems as needed. Each type of Performance System has unique advantages, depending upon your operation’s needs, and can be customized to fit the crop and drying needs of your farm. Shivvers designs and builds our drying equipment at one location, so we are confident in how each of our machines will perform, whether individually or within a system.

Shivvers System Components

A complete Shivvers System can be broken down into 6 core components that work together to deliver a comprehensive drying system. Each component can be purchased individually and combined with existing equipment, or together as a complete Shivvers Performance System.

Shivvers System Components

A complete Shivvers System can be broken down into 6 core components that work together to deliver a comprehensive drying system. Each component can be purchased individually and combined with existing equipment, or together as a complete Shivvers Performance System.